Home ProductsStone MachineryStone Factory MachinesStone Block Cutting MachinesCNC Diamond Wire Shaping Machine

PBO 5 Axes CNC Diamond Wire Saw Profiling Machine

FOB Price:

Type:

Stone Factory MachinesStone Block Cutting MachinesCNC Diamond Wire Shaping Machine

Usage:

Granite, Marble, Limestone, Quartzite, Sandstone, Travertine

After-Sale

Warranty:3 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Regular guidance & maintenance

You may also like

Machinery Function Features

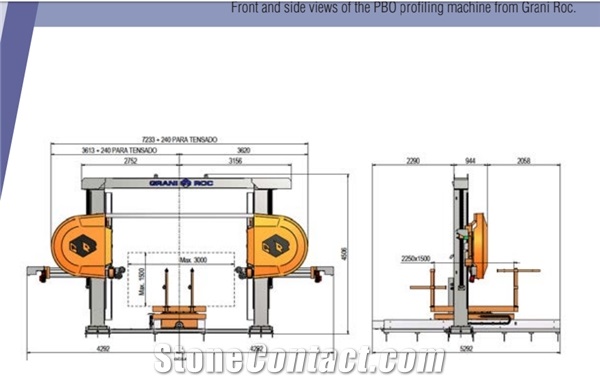

The PBO profiling machine of GRANI ROC is designed for a high precision dressing of blocks and slabbing and profiling production from stone blocks. The machine is composed of a static structure and a mobile trolley. All the movements are controlled by a 5 axes CNC panel board.

· The movements of the machine are controlled by a 5 axes CNC. The data can be input directly in the CNC or by an ISO code file generated by the CAD-CAM software GraniCAD supplied with the machine. This software allows to design the pieces to be profiled, to transfer the *.dxf files to the CNC, to define the parameters of cutting in each step of the cut (speed of cutting, speed of the wire, etc.) and to simulate the path of the wire during the cut.

· The machine has an electric system for bringing closer the small guide wheels that allows the operator to adjust the cutting width until the one desired, reducing the arch value when cutting with diamond wire and thereby increasing its speed

· The guiding wheels are controlled by the CNC and independent motors which allows to position the wheels in the direction of the cut, permitting a faster speed of cutting when profiling.

· The structure of the pillars and beam is made of electro welded and machined tubes. The trolley is composed of electro welded tubes forming a framework protecting all sensitive parts of the trolley: screws, wheels, etc.

· The tensioning of the wire is made pneumatic and automatically with indication of wire breakage or shortage. In this way the machine controls automatically the down movement of the machine, adapting it to the optimum working tension of the wire, avoiding possible breakages and optimizing its behaviour.

· All the main pulleys –drive and tensioning– and guiding wheels are protected by rubber liners in order to get the necessary traction of the wire. Such liners can be easily changed once they are worn out

· The machine is equipped with an automatic cooling system for the diamond wire with detection of constant water pressure. This system stops the machine in the case of lack or insufficient water flow, protecting the tool and preventing possible deterioration or damage of the equipment.

· All the up and down screws are protected with hoods against dust and water

· The machines has an automatic greasing system that injects lubricating liquid in the critical parts of the machine ensuring their correct functioning and the long life of the spare parts.

· The control panel has all the drive and protection components and devices of all control and safety equipment of the machine. All these components are standard, allowing easy and quick maintenance and / or replacement.

· The motorised 360º turntable trolley is controlled by the CNC and has a “Backlash” system that permit the production of complex shapes as balls, screws, etc.

· The movements of the machine are controlled by a 5 axes CNC. The data can be input directly in the CNC or by an ISO code file generated by the CAD-CAM software GraniCAD supplied with the machine. This software allows to design the pieces to be profiled, to transfer the *.dxf files to the CNC, to define the parameters of cutting in each step of the cut (speed of cutting, speed of the wire, etc.) and to simulate the path of the wire during the cut.

· The machine has an electric system for bringing closer the small guide wheels that allows the operator to adjust the cutting width until the one desired, reducing the arch value when cutting with diamond wire and thereby increasing its speed

· The guiding wheels are controlled by the CNC and independent motors which allows to position the wheels in the direction of the cut, permitting a faster speed of cutting when profiling.

· The structure of the pillars and beam is made of electro welded and machined tubes. The trolley is composed of electro welded tubes forming a framework protecting all sensitive parts of the trolley: screws, wheels, etc.

· The tensioning of the wire is made pneumatic and automatically with indication of wire breakage or shortage. In this way the machine controls automatically the down movement of the machine, adapting it to the optimum working tension of the wire, avoiding possible breakages and optimizing its behaviour.

· All the main pulleys –drive and tensioning– and guiding wheels are protected by rubber liners in order to get the necessary traction of the wire. Such liners can be easily changed once they are worn out

· The machine is equipped with an automatic cooling system for the diamond wire with detection of constant water pressure. This system stops the machine in the case of lack or insufficient water flow, protecting the tool and preventing possible deterioration or damage of the equipment.

· All the up and down screws are protected with hoods against dust and water

· The machines has an automatic greasing system that injects lubricating liquid in the critical parts of the machine ensuring their correct functioning and the long life of the spare parts.

· The control panel has all the drive and protection components and devices of all control and safety equipment of the machine. All these components are standard, allowing easy and quick maintenance and / or replacement.

· The motorised 360º turntable trolley is controlled by the CNC and has a “Backlash” system that permit the production of complex shapes as balls, screws, etc.

Technical Data

Parameters |

Unit |

PBO 2000 |

PBO 2500 |

Downfeed speed of the wire |

mm |

0 - 9000 |

0 - 9000 |

Total installed power |

kw |

15 |

17 |

Diameter of the main wheels |

mm |

1500 |

1500 |

Approximative Weight |

Kg |

7800 |

8000 |

Block-holding trolley dimensions |

mm |

1500 x 2250 |

1500 x 2250 |

Electrical connection |

V |

3 x 380 V + T + N |

3 x 380 V + T + N |

Downfeed speed of the wire |

mm/min |

0 - 675 |

0 - 675 |

Block min. widht |

mm |

1300 |

1800 |

Overall widht |

mm |

4600 |

4600 |

Overall height |

mm |

4506 |

4506 |

Wire peripheral speed |

mm/s |

0-40 |

0-40 |

Block max. height |

mm |

1500 |

1500 |

Diameter of the guiding wheels |

mm |

180 |

180 |

Block max. widht |

mm |

2500 |

3000 |

Wire actuating motor power |

kw |

7.5 |

7.5 |

Overall dimensions (without perimeter fencing) lenght |

mm |

7233+240 Rail |

7233+240 Rail |

Diamond wire length |

m |

15 |

16 |

Block max. weight |

Kg |

7200 |

8700 |

Block length |

mm |

1900 |

2500 |

Software

The movements of the machine are controlled by a 5 axes CNC. The data can be input directly in the CNC or by an ISO code file generated by the CAD-CAM software GraniCAD supplied with the machine. This software allows to design the pieces to be profiled, to transfer the *.dxf files to the CNC, to define the parameters of cutting in each step of the cut (speed of cutting, speed of the wire, etc.) and to simulate the path of the wire during the cut.

Recommended CNC Diamond Wire Shaping Machine Products

Related Products:

Machinery

Factory Machines

Stone Block Cutting Machines

Cnc Diamond Wire Shaping Machine

Granite Cnc Diamond Wire Shaping Machine

Marble Cnc Diamond Wire Shaping Machine

Limestone Cnc Diamond Wire Shaping Machine

Quartzite Cnc Diamond Wire Shaping Machine

Sandstone Cnc Diamond Wire Shaping Machine

Travertine Cnc Diamond Wire Shaping Machine

Grani Roc Machines

Alailson Vescovi

Alailson Vescovi