Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

Hct-A Cnc Stoneworking Center

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

Usage:

Granite, Marble, Limestone, Artificial Stone, Basalt, Quartzite

After-Sale

Warranty:24 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Remote troubleshooting

Machinery Function Features

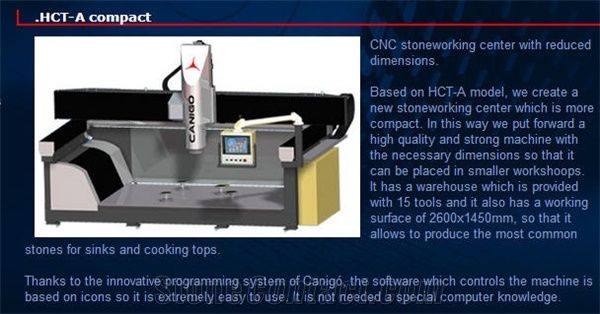

CNC stoneworking center with reduced dimensions.

Based on HCT-A model, we create a new stoneworking center which is more compact. In this way we put forward a high quality and strong machine with the necessary dimensions so that it can be placed in smaller workshoops.

It has a warehouse which is provided with 15 tools and it also has a working surface of 2600x1450mm, so that it allows to produce the most common stones for sinks and cooking tops.

Thanks to the innovative programming system of Canigó, the software which controls the machine is based on icons so it is extremely easy to use. It is not needed a special computer knowledge.

HCT-A compact machine is the opportunity for automate any workshop without the handicap of the machine dimensions and price.

UNIVERSAL WORK CENTER model HCT-A compact

STANDARD TECHNICAL CHARACTERISTICS

MOTORS

Disk motor power................................................................................ 5,5 KW

Adjustable turning speed of the head engine...................................... 7000 rpm

HEAD

No titling head.

Cutting systems................................................................................... Drill

Systems of the tools fixation............................................................... Automatic

AXIS STROKES AND MOVEMENTS

Vertical stroke of the head (axis Z)..................................................... 400 mm

Vertical movement of the head........................................................... Automatic

Transversal stroke of the bridge (axis Y)............................................ 1450 mm

Transversal movement of the bridge................................................... Automatic

Longitudinal stroke of the bridge (axis X)............................................ 2600 mm

Longitudinal movement of the bridge.................................................. Automatic

TABLE

Useful table surface…......................................................................... 2600x1450 mm

AUTOMATISMS

Laser pointer for the positioning of the material.

Automatic system of change of tools.

STRUCTURE AND COMPONENTS

Store of tools for 15 units..

Fixation of the material through adjustable suction pads.

Centralized lubrication.

Remote control for the manual positioning of the head.

TECHNICAL DATAS

Pressure of compressed air................................................................ 6 bars

Approximate net weight of the machine and accessories................... 4000 Kg.

External sizes of the machine............................................................. 4810x2950x2920 mm

INCLUDES THE FOLLOWING SERVICES

Vacuum plant with 4 suction pads of double effect of 120 mm.

Basic kit of tools and locking cones.

Training course

Based on HCT-A model, we create a new stoneworking center which is more compact. In this way we put forward a high quality and strong machine with the necessary dimensions so that it can be placed in smaller workshoops.

It has a warehouse which is provided with 15 tools and it also has a working surface of 2600x1450mm, so that it allows to produce the most common stones for sinks and cooking tops.

Thanks to the innovative programming system of Canigó, the software which controls the machine is based on icons so it is extremely easy to use. It is not needed a special computer knowledge.

HCT-A compact machine is the opportunity for automate any workshop without the handicap of the machine dimensions and price.

UNIVERSAL WORK CENTER model HCT-A compact

STANDARD TECHNICAL CHARACTERISTICS

MOTORS

Disk motor power................................................................................ 5,5 KW

Adjustable turning speed of the head engine...................................... 7000 rpm

HEAD

No titling head.

Cutting systems................................................................................... Drill

Systems of the tools fixation............................................................... Automatic

AXIS STROKES AND MOVEMENTS

Vertical stroke of the head (axis Z)..................................................... 400 mm

Vertical movement of the head........................................................... Automatic

Transversal stroke of the bridge (axis Y)............................................ 1450 mm

Transversal movement of the bridge................................................... Automatic

Longitudinal stroke of the bridge (axis X)............................................ 2600 mm

Longitudinal movement of the bridge.................................................. Automatic

TABLE

Useful table surface…......................................................................... 2600x1450 mm

AUTOMATISMS

Laser pointer for the positioning of the material.

Automatic system of change of tools.

STRUCTURE AND COMPONENTS

Store of tools for 15 units..

Fixation of the material through adjustable suction pads.

Centralized lubrication.

Remote control for the manual positioning of the head.

TECHNICAL DATAS

Pressure of compressed air................................................................ 6 bars

Approximate net weight of the machine and accessories................... 4000 Kg.

External sizes of the machine............................................................. 4810x2950x2920 mm

INCLUDES THE FOLLOWING SERVICES

Vacuum plant with 4 suction pads of double effect of 120 mm.

Basic kit of tools and locking cones.

Training course

Technical Data

Parameters |

Unit |

Hct-A |

Tool-holder spindle rotation speed |

r/min |

7000 |

Dimensions of the work table (length x width) |

mm |

2600x1450 |

Z axis stroke |

mm |

400 |

Machine overall height |

mm |

2920 |

X axis stroke |

mm |

2600 |

Machine overall length |

mm |

4810 |

Tool-holder spindle motor power |

kw |

5.5 |

Approx. Weight |

Kg |

4000 |

Y axis stroke |

mm |

1450 |

Machine overall width |

mm |

2950 |

Related Products:

Jordina Hereu

Jordina Hereu