Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

MTB/3 ANTIMUS BABY - Automatic Machine for Cutting and Edge Bevelling

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Usage:

Granite, Marble, Limestone, Artificial Stone, Basalt, Quartzite, Sandstone

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Remote troubleshooting

You may also like

Machinery Function Features

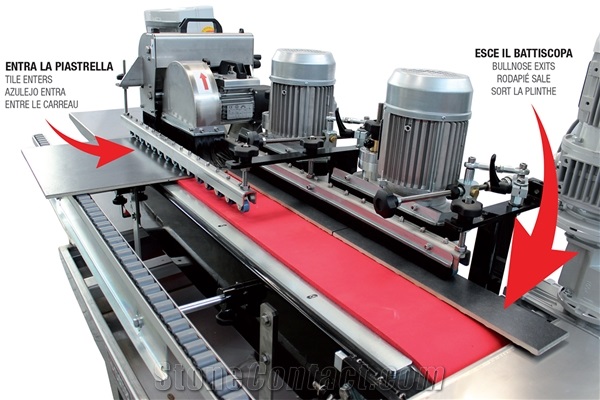

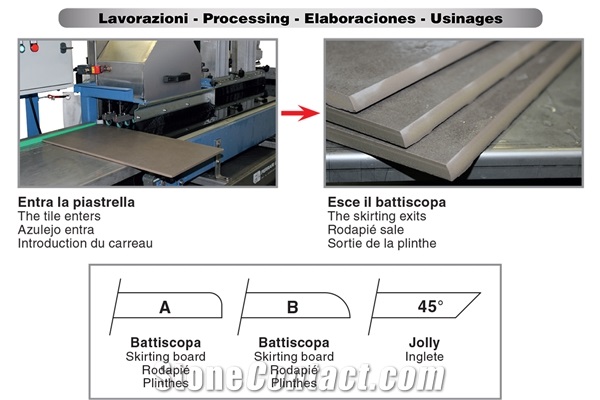

AUTOMATIC MACHINE FOR CUTTING AND EDGE-BEVELLING

MTB/3 ANTIMUS baby is the first and only compact, automatic machine able to cut and profile skirting pieces in a single passage!

It is a revolutionary machine that meets the needs of ceramic, marble and stone laboratories, with small to medium productions.

Until now such workshops either had to use two separate manual machines (one for cutting and one for edge-profiling) or rely upon external service companies, with an incredible loss of time.

MTB/3 ANTIMUS - AUTOMATIC MACHINE FOR CUTTING AND EDGE-BEVELLING

PATENTED

CUTTING AND PROFILING IN ONLY 1 STEP AND WITH ONLY 1 MACHINE

MTB/3 ANTIMUS is the first and only compact, automatic belt machine able to carry out in a single passage and with just one movement of the piece, both the cutting and the profiling of the skirting! It is a revolutionary machine that meets the needs of ceramic, marble and stone workshops, with small to medium weekly production needs. Until now such workshops either had to use two separate manual machines (one for cutting and one for edge-profiling) or rely upon external service companies, with an incredible loss of time.

ADVANTAGES OF MTB/3 ANTIMUS SYSTEM

Minimum dimension

Monoblock machine

Low consumption of electric energy

Constancy of production quality

Very low initial investment

Total automation of production cycle

"END WORKING CYCLE": tile enters and bullnose goes out, without any necessary movement from the operator

MTB/3 ANTIMUS baby is the first and only compact, automatic machine able to cut and profile skirting pieces in a single passage!

It is a revolutionary machine that meets the needs of ceramic, marble and stone laboratories, with small to medium productions.

Until now such workshops either had to use two separate manual machines (one for cutting and one for edge-profiling) or rely upon external service companies, with an incredible loss of time.

MTB/3 ANTIMUS - AUTOMATIC MACHINE FOR CUTTING AND EDGE-BEVELLING

PATENTED

CUTTING AND PROFILING IN ONLY 1 STEP AND WITH ONLY 1 MACHINE

MTB/3 ANTIMUS is the first and only compact, automatic belt machine able to carry out in a single passage and with just one movement of the piece, both the cutting and the profiling of the skirting! It is a revolutionary machine that meets the needs of ceramic, marble and stone workshops, with small to medium weekly production needs. Until now such workshops either had to use two separate manual machines (one for cutting and one for edge-profiling) or rely upon external service companies, with an incredible loss of time.

ADVANTAGES OF MTB/3 ANTIMUS SYSTEM

Minimum dimension

Monoblock machine

Low consumption of electric energy

Constancy of production quality

Very low initial investment

Total automation of production cycle

"END WORKING CYCLE": tile enters and bullnose goes out, without any necessary movement from the operator

Technical Data

Parameters |

Unit |

MTB/3 ANTIMUS BABY |

MTB/3 ANTIMUS |

Machine overall length |

mm |

760 |

1000 |

Water consumption |

L/min |

200 |

200 |

Machine overall width |

mm |

2300 |

2950 |

Total power |

kw |

6 |

8 |

Number of dressing/polishing spindles |

nr |

2 |

2 |

Voltage |

V |

400 V-50HZ |

400 V-50HZ |

Machine overall height |

mm |

1300 |

1800 |

Standard diameter of polishing wheels |

mm |

140 |

140 |

Max. processing thickness |

mm |

12 |

20 |

Min. processing thickness |

mm |

6 |

6 |

Approx. Weight |

Kg |

260 |

350 |

Dimension obtained |

mm |

50 a 60 |

50 a 120 |

Grinding tool diameter |

mm |

140 |

140 |

Number of Bevelling/chamfering spindles |

nr |

2 |

2 |

Diameter of the drip board saw blade |

mm |

250 |

300 |

Hydraulic pump power |

kw |

0,37 |

0,37 |

No. calibrating/shaping/cutting spindles |

nr |

1 |

1 |

Conveyor Belt width |

mm |

200 |

350 |

Recommended Edge Profiling, Polishing Machine Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Edge Profiling Polishing Machine

Granite Edge Profiling Polishing Machine

Marble Edge Profiling Polishing Machine

Limestone Edge Profiling Polishing Machine

Artificial Stone Edge Profiling Polishing Machine

Basalt Edge Profiling Polishing Machine

Quartzite Edge Profiling Polishing Machine

Sandstone Edge Profiling Polishing Machine

Compactline Machines

Luca Armagno

Luca Armagno