Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

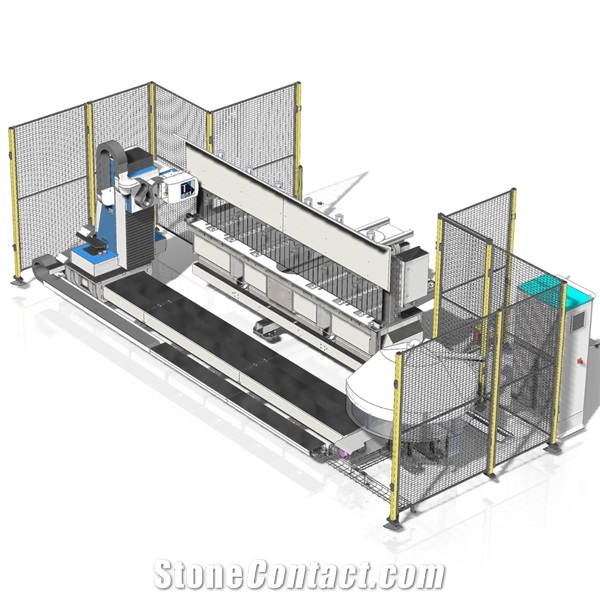

T658 CNC Multipurpose Edge Profiling and Polishing Center with Automatic Loader

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Usage:

Granite, Marble, Limestone, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Online software upgrade, Remote troubleshooting, Field troubleshooting

Machinery Function Features

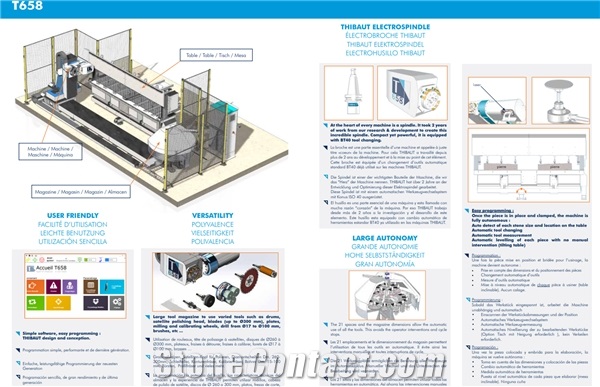

USER FRIENDLY

We have designed a simple, attractive and innovative software. It runs under Windows 10.

VERSATILITY

THIBAUT know-how combines easy programming, spindle power, a large tool magazine to use varied tools such as drums, B3 polishing head (patented), blades (up to Ø300 mm), plates, milling and calibrating wheels, drill from Ø17 to Ø100 mm, brushes, etc…

THIBAUT ELECTROSPINDLE

At the heart of every machine is a spindle. It took 2 years of work from our research & development to create this incredible spindle. Compact yet powerful, it is equipped with BT40 tool changing.

LARGE AUTONOMY

Easy programming :

• Once the piece is in place and clamped, the machine is fully autonomous :

– Auto-detect of each stone size and location on the table

– Automatic tool changing

– Automatic tool measurement

– Automatic levelling of each piece with no manual intervention (tilting table)

Tools magazine :

The 21 spaces and the magazine dimensions allow the automatic use of all the tools. This avoids operator interventions and the cycle stops.

POSSIBLE VERSIONS

FIXED TABLE

• Automatic trueing bar

• Fixed clamping bridge

• Retractable omnidirectional roller

• Manual turning plate

• Side trueing

TILTING TABLE

• Automatic trueing bar

• Fixed or retractable clamping bridge

• Manual or automatic turning plate

• Side trueing

APPLICATIONS

• MONUMENT

• COUNTERTOPS

• CONSTRUCTION

We have designed a simple, attractive and innovative software. It runs under Windows 10.

VERSATILITY

THIBAUT know-how combines easy programming, spindle power, a large tool magazine to use varied tools such as drums, B3 polishing head (patented), blades (up to Ø300 mm), plates, milling and calibrating wheels, drill from Ø17 to Ø100 mm, brushes, etc…

THIBAUT ELECTROSPINDLE

At the heart of every machine is a spindle. It took 2 years of work from our research & development to create this incredible spindle. Compact yet powerful, it is equipped with BT40 tool changing.

LARGE AUTONOMY

Easy programming :

• Once the piece is in place and clamped, the machine is fully autonomous :

– Auto-detect of each stone size and location on the table

– Automatic tool changing

– Automatic tool measurement

– Automatic levelling of each piece with no manual intervention (tilting table)

Tools magazine :

The 21 spaces and the magazine dimensions allow the automatic use of all the tools. This avoids operator interventions and the cycle stops.

POSSIBLE VERSIONS

FIXED TABLE

• Automatic trueing bar

• Fixed clamping bridge

• Retractable omnidirectional roller

• Manual turning plate

• Side trueing

TILTING TABLE

• Automatic trueing bar

• Fixed or retractable clamping bridge

• Manual or automatic turning plate

• Side trueing

APPLICATIONS

• MONUMENT

• COUNTERTOPS

• CONSTRUCTION

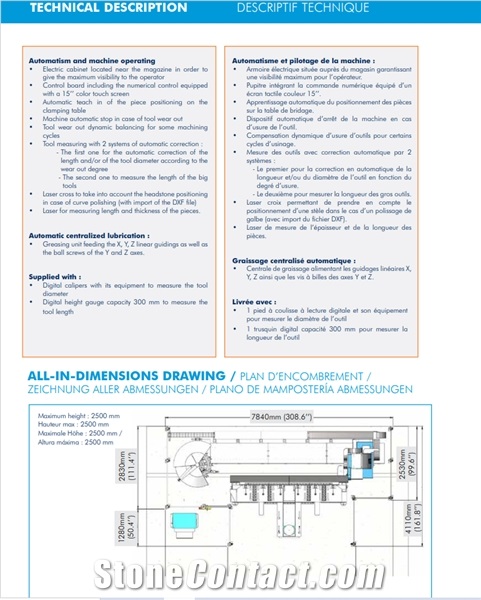

Technical Data

Parameters |

Unit |

T658 |

Dressing/polishing spindle power |

kw |

8.8 Kw in S1 (at 3000 rpm) |

Machine overall length |

mm |

7840 |

Min. processing thickness |

mm |

10 |

Machine overall height |

mm |

2500 |

Max. processing thickness |

mm |

400 |

A axis (spindle orientation) |

° |

+/- 90° |

Machine overall width |

mm |

2830+1280 |

Voltage |

V/Hz |

400 V / 50 Hz |

Polishing spindle rotation speed |

r/min |

0 to 5000 |

Max. workable length of the single piece |

mm |

3600 |

Recommended Edge Profiling, Polishing Machine Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Edge Profiling Polishing Machine

Granite Edge Profiling Polishing Machine

Marble Edge Profiling Polishing Machine

Limestone Edge Profiling Polishing Machine

Onyx Edge Profiling Polishing Machine

Artificial Stone Edge Profiling Polishing Machine

Basalt Edge Profiling Polishing Machine

Quartzite Edge Profiling Polishing Machine

Sandstone Edge Profiling Polishing Machine

Travertine Edge Profiling Polishing Machine

Thibaut Machines

Baptiste Lebouteiller

Baptiste Lebouteiller