Home ProductsStone MachineryStone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

Heavy QSDQ Hydraulic Bridge Block Cutting Machine

FOB Price:$39900-49000

Type:

Stone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

Usage:

Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Lead Time:

35 days

Warranty:12 Months

Install and Guarantee:Remote guidance installation

Maintenance:Remote troubleshooting

Trade Terms

Port:

XIAMEN- China

Delivery Details: FOB,CFR,CIF,EXW,Express Delivery

Payment :

You may also like

Machinery Function Features

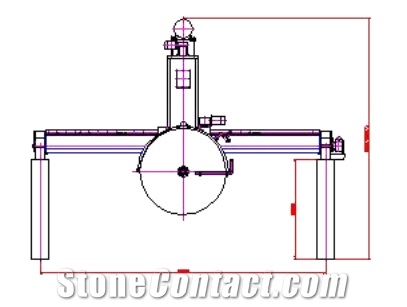

Hydraulic Bridge block cutting machine is a large board that cuts stone material into the specified thickness quickly and accurately according to requirements.

The bridge type stone machine is suitable for both granite and marble. It is convenient to replace the saw blade, has large processing specifications, flexible adjustment and processing thickness. It is widely used for large-scale block cutting and profiled blank material cutting.

Product Overview

Our company has many years of experience in bridge hydraulic cutting production. The bridge hydraulic large cut installable saw blade can be selected from 1.6 meters to 3.2 meters.

The girders can reach a maximum length of 10 meters, and the industry is in a leading position. The bridge hydraulic combination cutting machine adopts hydraulic four-column lifting structure, oil-immersed sealed guide rail and Taiwan brand hydraulic system. The electronic control system of international famous brands produces high efficiency, good flatness, low failure rate and high safety factor.

Product trait

The beam can be made up to a length of 10 meters and a height of 800mm and a width of 700mm. The guide column is made of 180mm solid round steel. The weight is sufficient, the equipment is more stable, and two blocks can be cut at the same time, which greatly improves the output and quality. The hydraulic system adopts the Taiwan brand. Stable and reliable, electronic control products can be equipped with German Schneider, Japan Omron, Germany Weidmuller, and domestic mainstream brands such as easy-drive and other international brand products, product composition, to achieve full automation control of the stone cutting process, making safe and reliable operation The imported programming controller is used as the core, and the man-machine interface operation is realized through computer communication, and the modification of the working parameters, the real-time monitoring of the working state, and the diagnosis and debugging are completed, and the reliable control ensures the production safety.

The bridge type stone machine is suitable for both granite and marble. It is convenient to replace the saw blade, has large processing specifications, flexible adjustment and processing thickness. It is widely used for large-scale block cutting and profiled blank material cutting.

Product Overview

Our company has many years of experience in bridge hydraulic cutting production. The bridge hydraulic large cut installable saw blade can be selected from 1.6 meters to 3.2 meters.

The girders can reach a maximum length of 10 meters, and the industry is in a leading position. The bridge hydraulic combination cutting machine adopts hydraulic four-column lifting structure, oil-immersed sealed guide rail and Taiwan brand hydraulic system. The electronic control system of international famous brands produces high efficiency, good flatness, low failure rate and high safety factor.

Product trait

The beam can be made up to a length of 10 meters and a height of 800mm and a width of 700mm. The guide column is made of 180mm solid round steel. The weight is sufficient, the equipment is more stable, and two blocks can be cut at the same time, which greatly improves the output and quality. The hydraulic system adopts the Taiwan brand. Stable and reliable, electronic control products can be equipped with German Schneider, Japan Omron, Germany Weidmuller, and domestic mainstream brands such as easy-drive and other international brand products, product composition, to achieve full automation control of the stone cutting process, making safe and reliable operation The imported programming controller is used as the core, and the man-machine interface operation is realized through computer communication, and the modification of the working parameters, the real-time monitoring of the working state, and the diagnosis and debugging are completed, and the reliable control ensures the production safety.

Technical Data

Parameters |

Unit |

QSDQ-2200 |

QSDQ-2500 |

QSDQ-2800 |

Maximum disc diameter |

mm |

2200 |

2500 |

2800 |

Machine height |

mm |

7000 |

7000 |

7000 |

Max. cutting depth |

mm |

950 |

1100 |

1250 |

Maximum block width |

mm |

2200 |

2200 |

2200 |

Approximate Weight |

Kg |

11500 |

12000 |

12500 |

Machine width |

mm |

4000 |

4000 |

4000 |

Maximum block length |

mm |

4200 |

3700 |

3500 |

Work Example

The structural parts of this machine (disc up/down unit, right/left moving unit, forward/backward moving structure, optional worktable with forward/backward device) are formed from cast iron giving unrivaled long life, precision, corrosion resistance and acoustic benefits. The surface preparation of the machine is starting with all the castings being sandblasted, washed and then the three layers of paint are applied.

- DISCUP/DOWN UNIT: The structure is in highly resistant cast iron. It adopts two slider frame structure, driven synchronizely by double screw with adjustable top and bottom limits.

- RIGHT/LEFTMOVING UNIT: The beam and moving frame is in highly resistant cast iron. it is driven by the rack and pinion which is connected with the reducer and motor

- BLADESPINDLE: The spindle is made of strong cast iron which is driven by the pulley. And use the SIMENS motor and SKF(Made in Sweden) bearing.

- FORWARD/BACKWARDMOVING STRUCTURE: it consists of right/left longitudinal beam, slider, synchronized screw; The beam is in highly resistant cast iron, guide in high stable. The motor is SIMENS motor

- OPTIONALTABLE ( BY ORDER) : made of highly resistant cast iron for maximum stability and duration, and a greater absorbency of vibrations and noise, the table with idler wheel is driven by screw

- ELECTRIC BOX AND CONTROL PANNEL: The electric box containing electric equipments. Control panel with all the commands controlling the movements. QSDQ-3200 is a PLC controlled machine. All the electric components including OMROM PLC (Made in Japan )and YIQU inverter are with stable and precise performance..

Recommended Giant Disc Bridge Saw Machine Products

Related Products:

Machinery

Factory Machines

Stone Block Cutting Machines

Giant Disc Bridge Saw Machine

Granite Giant Disc Bridge Saw Machine

Marble Giant Disc Bridge Saw Machine

Limestone Giant Disc Bridge Saw Machine

Slate Giant Disc Bridge Saw Machine

Onyx Giant Disc Bridge Saw Machine

Artificial Stone Giant Disc Bridge Saw Machine

Basalt Giant Disc Bridge Saw Machine

Quartzite Giant Disc Bridge Saw Machine

Sandstone Giant Disc Bridge Saw Machine

Travertine Giant Disc Bridge Saw Machine

Shuinan Machine Machines

4YR

4YR

Franco LIAO

Franco LIAO