Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesStone Carving Robot

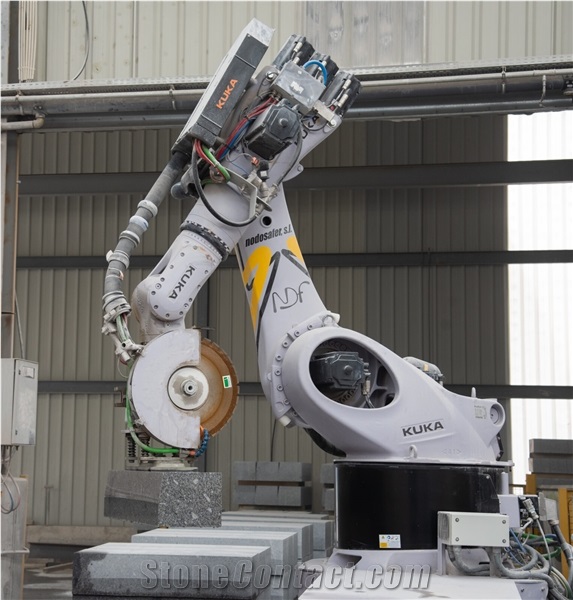

KUKA- Robots Cutting And Finishing Machine

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesStone Carving Robot

Usage:

Granite, Marble, Limestone, Slate, Onyx, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Online software upgrade, Remote troubleshooting, Field troubleshooting

Machinery Function Features

Robot for finishing and palletizing with articulated vacuum suction cup for granite curbs.

It is made up:

Robot mod. KR-360.

Chamfering group, disc housing, water diffuser, etc.

Flame torch, regulators, valves, etc.

Vacuum group, with pump, tank, suction cup, valves, etc.

Electrical panel, and control panel with touch screen.

Belt feeding table.

Curb bumping and squaring device.

Turning table for the elaboration of curbs.

Security fencing to limit access to the mobile part of the machine.

The Robot is specially designed to carry out automated tasks in the performance of curb finishing tasks, milling of edges or rounding, flaming of faces and their subsequent palletizing, based on the same operating principles applied in standard Nodosafer machining and palletizing, and offers multiple advantages: optimization of work processes, reduction of cycle times and efficient use of downtime, etc.

On the wrist of the Robot, a compact and specially designed head is implemented, on which the milling motor group is supported, the torch for flaming, as well as a suction cup for handling.

The reception suction cup, also of a particular design, is made up of a rectangular plate, capable of supporting horizontal loads of up to 160 kg.

The motorized belt table, located at the entrance of the Robot, constitutes the feeding point to the treatment unit. In addition, it acts as an intermediate warehouse to guarantee the fluidity of the work cycle and minimize downtime for the entire line. It basically consists of a frame based on steel profiles on which the roller shafts rest.

All the wheels are frictioned to thus facilitate the synchronism of the advancement speeds of the tiles throughout the line.

A double device for bumping and squaring located on the band table, allows the positioning and control of the curbs before they are received by the robot.

The turning table for the elaboration of the curbs is located in the work area of the robot and allows to greatly reduce the time during the elaboration process.

The work area is protected, limiting access to risk areas by means of protection fences and photocells, to avoid any risk of accident.

The programming and the work sequence is variable and parameterizable, it is done by selecting from the control panel.

It is made up:

Robot mod. KR-360.

Chamfering group, disc housing, water diffuser, etc.

Flame torch, regulators, valves, etc.

Vacuum group, with pump, tank, suction cup, valves, etc.

Electrical panel, and control panel with touch screen.

Belt feeding table.

Curb bumping and squaring device.

Turning table for the elaboration of curbs.

Security fencing to limit access to the mobile part of the machine.

The Robot is specially designed to carry out automated tasks in the performance of curb finishing tasks, milling of edges or rounding, flaming of faces and their subsequent palletizing, based on the same operating principles applied in standard Nodosafer machining and palletizing, and offers multiple advantages: optimization of work processes, reduction of cycle times and efficient use of downtime, etc.

On the wrist of the Robot, a compact and specially designed head is implemented, on which the milling motor group is supported, the torch for flaming, as well as a suction cup for handling.

The reception suction cup, also of a particular design, is made up of a rectangular plate, capable of supporting horizontal loads of up to 160 kg.

The motorized belt table, located at the entrance of the Robot, constitutes the feeding point to the treatment unit. In addition, it acts as an intermediate warehouse to guarantee the fluidity of the work cycle and minimize downtime for the entire line. It basically consists of a frame based on steel profiles on which the roller shafts rest.

All the wheels are frictioned to thus facilitate the synchronism of the advancement speeds of the tiles throughout the line.

A double device for bumping and squaring located on the band table, allows the positioning and control of the curbs before they are received by the robot.

The turning table for the elaboration of the curbs is located in the work area of the robot and allows to greatly reduce the time during the elaboration process.

The work area is protected, limiting access to risk areas by means of protection fences and photocells, to avoid any risk of accident.

The programming and the work sequence is variable and parameterizable, it is done by selecting from the control panel.

Technical Data

Parameters |

Unit |

KUKA- Robot |

Forward speed |

m/min |

11.5 |

Width max. worked |

mm |

2200 |

Weight capacity on the wirst |

Kg |

360 |

Drive motor power |

hp |

2 |

Spindle nominal power |

hp |

10 |

Installed power |

hp |

50 |

Air consumption |

m3/h |

90 |

Length max. of the table |

mm |

2500 |

Work table width |

mm |

2930 |

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Stone Carving Robot

Granite Carving Robot

Marble Carving Robot

Limestone Carving Robot

Slate Carving Robot

Onyx Carving Robot

Basalt Carving Robot

Quartzite Carving Robot

Sandstone Carving Robot

Travertine Carving Robot

Nodosafer Machines

Jose Manuel Lopez Guitian

Jose Manuel Lopez Guitian