Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

SCHIND CMF01 Marble And Granite Chamfering Machine

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Usage:

Granite, Marble, Limestone, Onyx, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Remote troubleshooting, Field troubleshooting

You may also like

Machinery Function Features

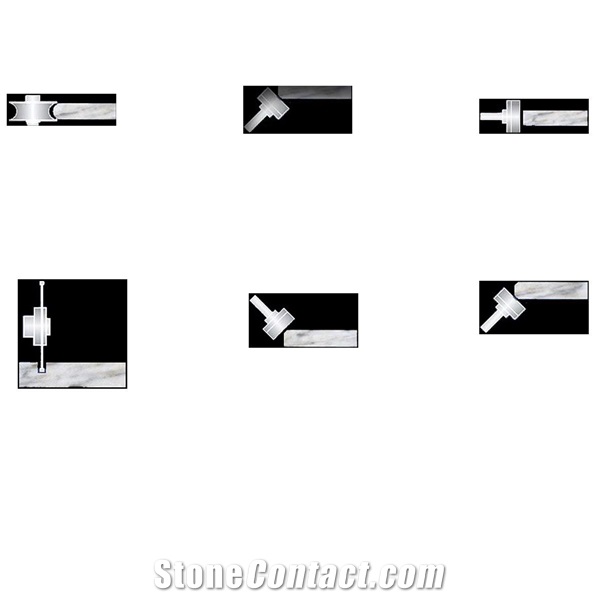

Our surface polishing marble granite chamfering machine provides series and standard production.

Our fully automatic polishing machine is easy to use and maintain, and it chamfers from the bottom.

Our machine is controlled by front panel and all heads are working independently of each other.

The polishing heads automatically work and come out just after the entrance of the stone till finishing the relevant area, then automatically turns off and goes back.

Heads can be disabled according to the process.

The polished part of the marble must be placed on the production belt.

Conveyor belt movement is electronic speed controlled and width is 450mm...

Our machine is produced as 6+2, 8+2, 10+2, 12+2, 14+2 standard according to the sort of natural stone.

Our 12+2 machine has 1 caliber, 5 bottom chamfer, 6 side chamfer, 1 deburring and 1 drip saw.

The machine can process minimum 70/80 mm and up to 1500 mm with a bottom supported compasses mechanism.

The engine section of the machine is completely protected from water by internal and external protective parts.

The protective panels are opened and closed with the help of shock absorbers for lubrication channels maintenance and abrasive replacement.

Felt is used to be resistant of heat and abrasion to protect the head bearings behind the abrasive.

If the customer wants our machine can be integrated into the herringbone diamond.

Our fully automatic polishing machine is easy to use and maintain, and it chamfers from the bottom.

Our machine is controlled by front panel and all heads are working independently of each other.

The polishing heads automatically work and come out just after the entrance of the stone till finishing the relevant area, then automatically turns off and goes back.

Heads can be disabled according to the process.

The polished part of the marble must be placed on the production belt.

Conveyor belt movement is electronic speed controlled and width is 450mm...

Our machine is produced as 6+2, 8+2, 10+2, 12+2, 14+2 standard according to the sort of natural stone.

Our 12+2 machine has 1 caliber, 5 bottom chamfer, 6 side chamfer, 1 deburring and 1 drip saw.

The machine can process minimum 70/80 mm and up to 1500 mm with a bottom supported compasses mechanism.

The engine section of the machine is completely protected from water by internal and external protective parts.

The protective panels are opened and closed with the help of shock absorbers for lubrication channels maintenance and abrasive replacement.

Felt is used to be resistant of heat and abrasion to protect the head bearings behind the abrasive.

If the customer wants our machine can be integrated into the herringbone diamond.

Technical Data

Parameters |

Unit |

CMF01 - 10+2 HEAD |

CMF01 - 12+2 HEAD |

CMF01 - 14+2 HEAD |

CMF01 - 16+2 HEAD |

Number of Bevelling/chamfering spindles |

nr |

4 |

5 |

6 |

7 |

No. calibrating/shaping/cutting spindles |

nr |

1 |

1 |

1 |

1 |

Saw Disc Diameter |

mm |

250 |

250 |

250 |

250 |

Min. processing thickness |

mm |

10 |

10 |

10 |

10 |

Machine overall height |

mm |

2100 |

2100 |

2100 |

2100 |

Max. processing thickness |

mm |

40 |

40 |

40 |

40 |

Dropper Saw Motor Power |

kw |

2.2 |

2.2 |

2.2 |

2.2 |

Opening Table Width |

mm |

1400 |

1400 |

1400 |

1400 |

Machine overall width |

mm |

1700 |

1700 |

1700 |

1700 |

Band Reducer Motor Power |

kw |

1.5 |

1.5 |

1.5 |

1.5 |

Total power |

kw |

21.00 |

25.50 |

29.50 |

34.50 |

Water consumption |

L/min |

32 |

35 |

40 |

45 |

Dressing/polishing spindle power |

kw |

1.5 |

1.5 |

1.5 |

1.5 |

Calibrating/shaping/cutting spindle power |

kw |

2.2 |

2.2 |

2.2 |

2.2 |

Number of dressing/polishing spindles |

nr |

5 |

6 |

7 |

8 |

Machine overall length |

mm |

7100 |

7500 |

8100 |

8500 |

Bevelling /Chamfering spindle power |

kw |

1.5 |

1.5 |

1.5 |

1.5 |

Belt advancement speed |

m/h |

0 - 35 |

0 - 35 |

0 - 35 |

0 - 35 |

Min. Cooling water pressure |

bar |

1-3 |

1-3 |

1-3 |

1-3 |

Min. processing width |

mm |

70 |

70 |

70 |

70 |

Upper Pressure Motor Power |

kw |

0.75 |

0.75 |

0.75 |

0.75 |

Power of the disk for drip groove execution |

kw |

1.5 |

1.5 |

1.5 |

1.5 |

Recommended Edge Profiling, Polishing Machine Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Edge Profiling Polishing Machine

Granite Edge Profiling Polishing Machine

Marble Edge Profiling Polishing Machine

Limestone Edge Profiling Polishing Machine

Onyx Edge Profiling Polishing Machine

Quartzite Edge Profiling Polishing Machine

Sandstone Edge Profiling Polishing Machine

Travertine Edge Profiling Polishing Machine

Schind Machines Machines

Yasin Ozkan

Yasin Ozkan